From grass to carpet

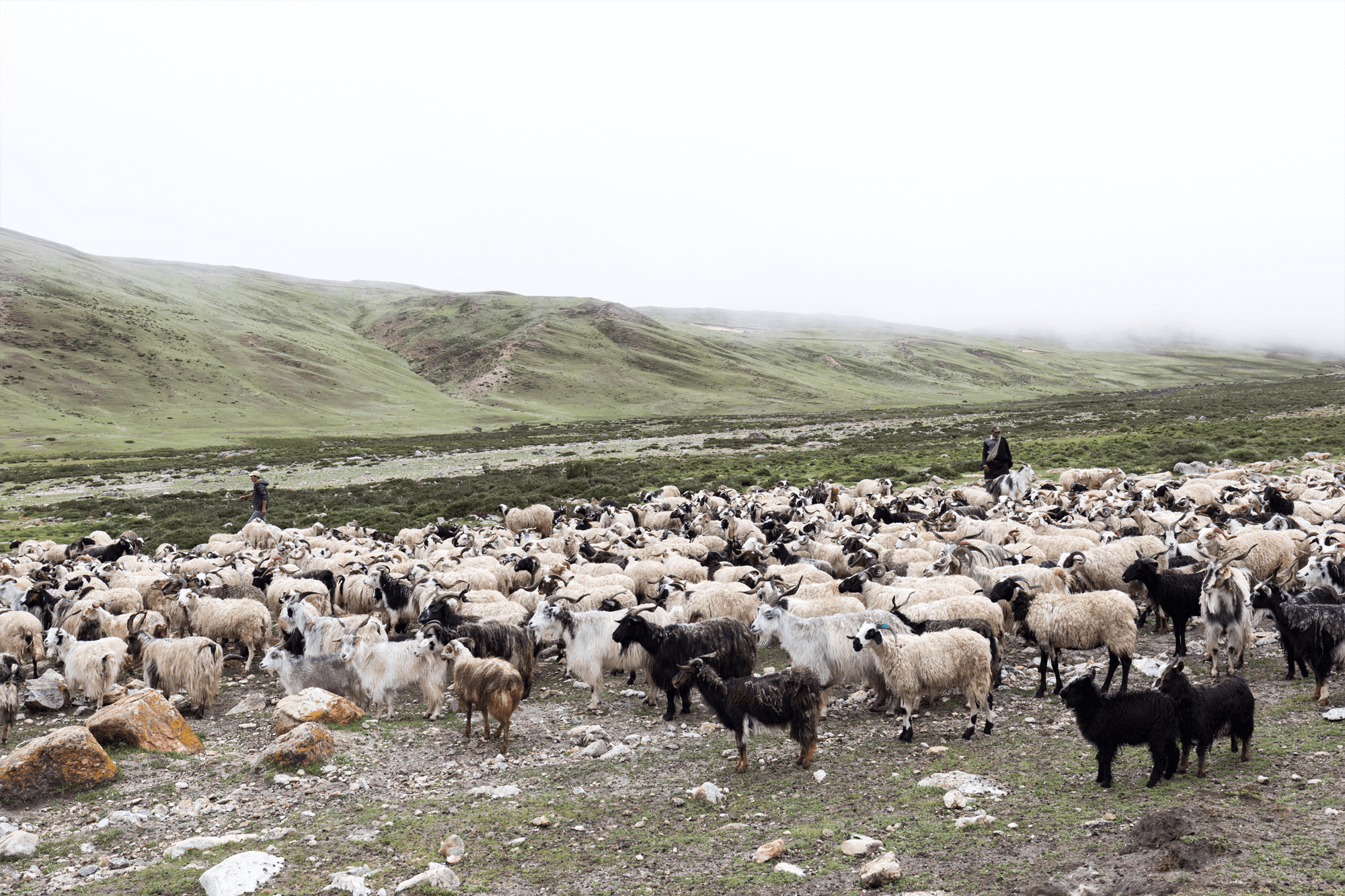

Our high-quality rugs actually begin in the field. The wool we use is from highland Tibetan sheep. The animals have a coat with very long fibers and a high percentage of lanolin to protect from their rough habitat. These properties are ideal for making durable carpets—provided the processing is done gently enough to preserve these natural properties.

Washing and Drying Highland Wool

To clean and dry the wool without losing the precious natural lanolin, the wool is cleaned, without chemicals, by washing it in a mountain stream at 4000 m. Any strands that are too heavily soiled are sorted out by hand. Afterwards the clean wool is laid out to dry in the sun.

Carding and Spinning

The wool, freshly washed and dried, is now carded by hand. Carding is a process that untangles the wool fibers, combing them until they all face the same direction. Now the wool is ready to be spun into yarn and then dyed. The yarn, hand-carded and hand-spun, takes on the colors in varying degrees of intensity, imbuing our rugs with unique character and charm.

Dying the Wool

The yarn is dyed using natural, environmentally friendly, plant-based colors. The colors are derived from Geba’s special color palette, a range of hues designed for harmonious combinations. The inherent nature of the hand-made wool ensures that colors are never 100% identical, but instead filled with slight variations that cause vibrancy. We use synthetic dyes when, for example, it is necessary to obtain an exact color match for an interior design concept.

Knotting Rugs

Our rugs are handmade in our workshops in Nepal. The families we work with use a traditional Tibetan loop knot that dates back thousands of years. This technique makes precise ornamentation and complex patterns possible while ensuring the robust durability necessary for everyday use.

Beyond Wool

To emphasize the design of a carpet, the pile can be sheared at varying heights. We sometimes complement our Tibetan highland wool with other materials, such as hemp, silk, linen, nettle, and more. We even make some rugs without any wool at all. Hemp rugs, for example, dry very quickly and are particularly suitable for entryways and spa areas. Let us know if you have an allergy or aversion to wool—we can use many other materials.

Final Cleaning

The final step is to wash each rug by hand. It is then stretched and slowly dried in the sun—a step that guarantees dimensional stability. The result is fine carpets with timeless quality, each with its own personal tale to tell.

The Final Product

The finished rug is inspected to ensure that our strict quality standards are met. It is then packaged, shipped to Austria, and put on display at the Geba carpet gallery. From here, the rugs find their way to purchasers in private homes and businesses.

Geba Fairtrade and the Label STEP®: Fair conditions for our partners

From sheep shearing to finished product, our rugs pass through many hands. It is important to us that these hands are motivated by joy and satisfaction, not by coercion or exploitation. This is why our production processes follow the rules of the STEP label—a fair trade non-profit organization committed to the wellbeing of weavers and workers in the handmade carpet industry. We are committed to social improvement and fair working conditions.

The Path to Making Rugs

This film was made in 2017 on Geba’s 30th anniversary with the aim of showing our carpet craftsmanship from start to finish. With a cameraman and a photographer, we documented the long journey of Geba rugs from the workshops to the carpet gallery in Graz.

Duration: 13:30 minutes